Application / Product Range:

• For drawing bare or tinned copper wire.

• Nº of wires: 1 or 2.

Technical data

(we reserve the right to modify technical data and characteristics at any time):

• Wet wire drawing machine for non-ferrous materials.

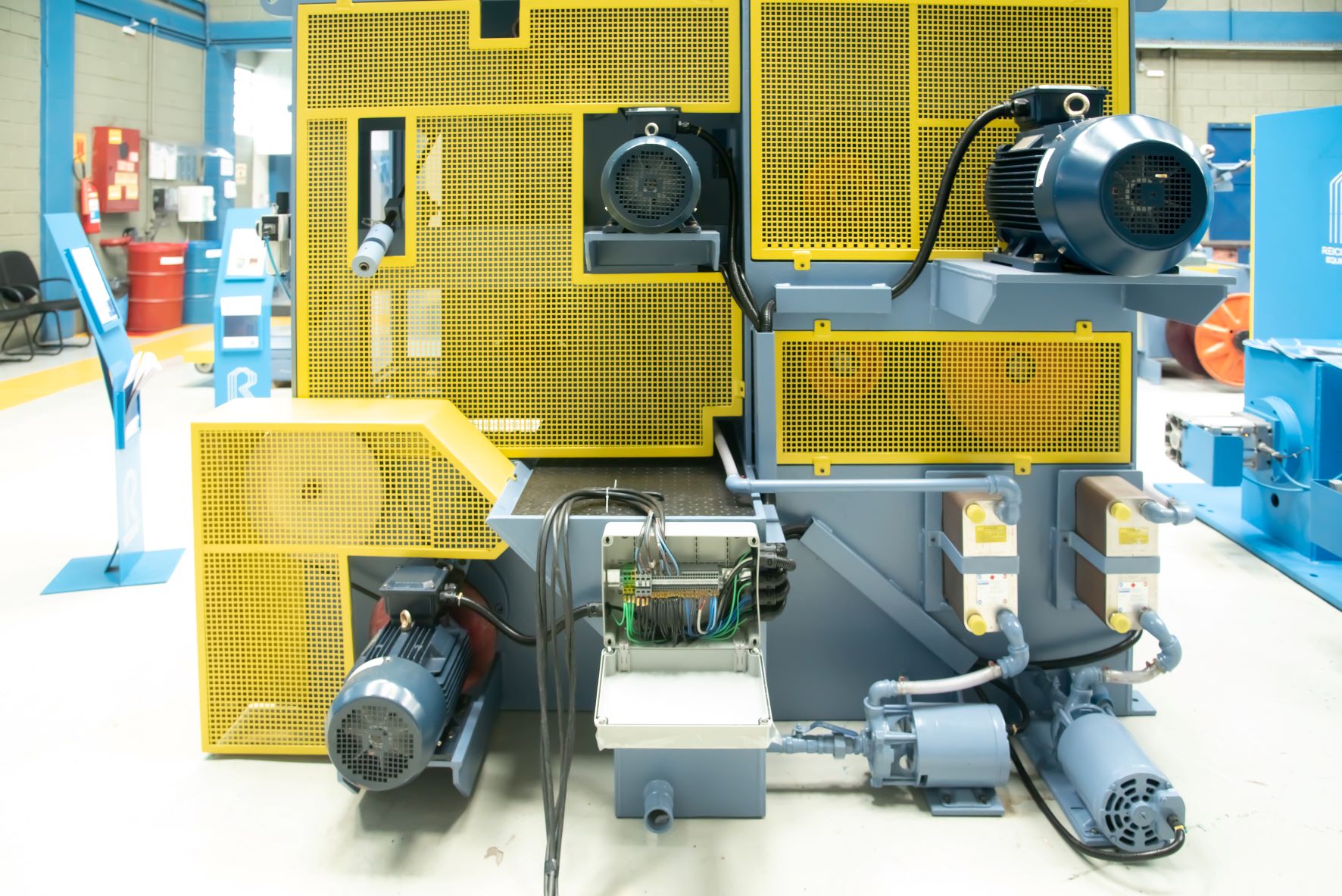

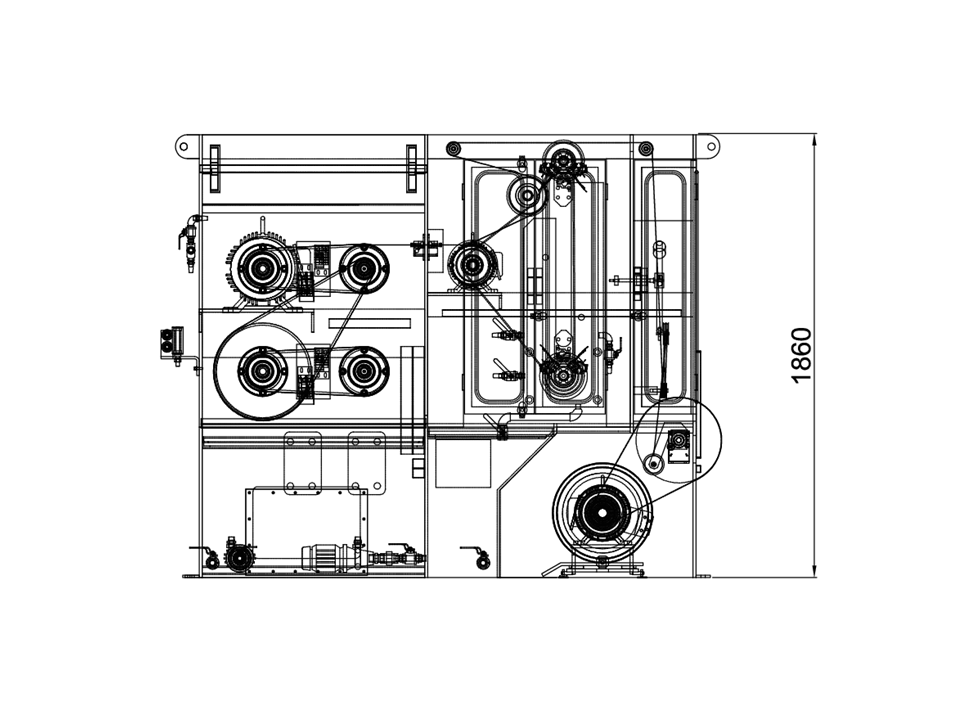

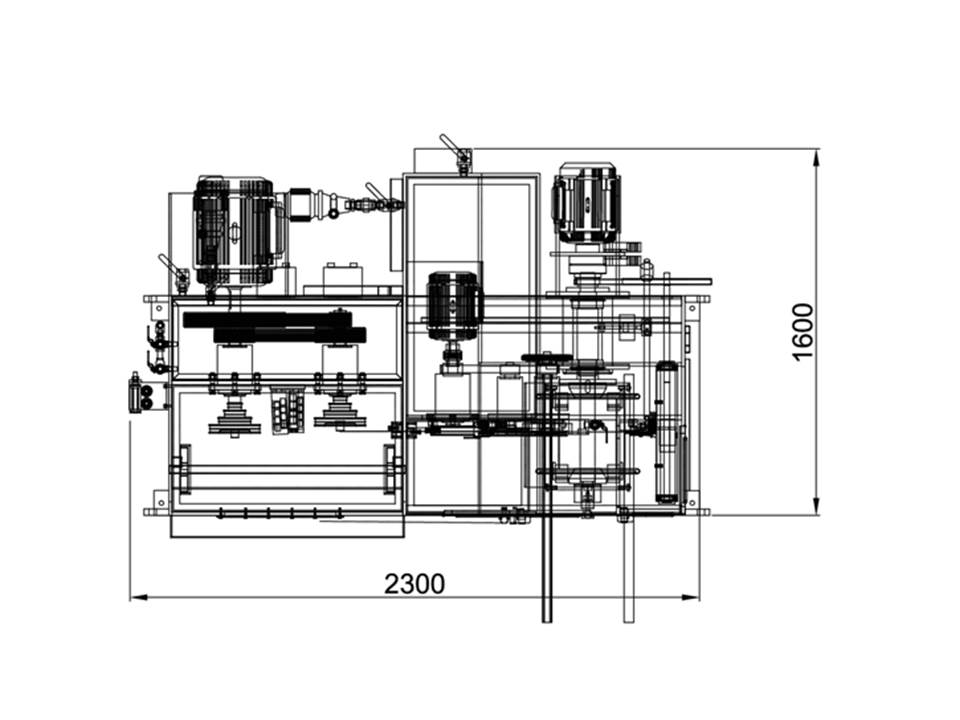

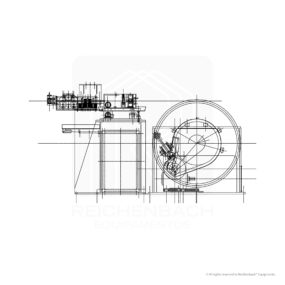

• Compact Construction – Wire drawing machine + Annealer + Controller Dancer + Take Up.

• Direction of operation: Right.

• Maximum operating speed (bare copper): 25m/s

• Maximum operating speed (tinned copper): 20m/s

• Max. inlet ø mm: 1.83.

• Min./Max. ø outlet mm: 0.160 – 0.404 with 2 wires.

0.455 – 0.577 with 1 wire.

• System for quick change of diameter, replacing only the last die and keeping the internal dies in their positions.

• Reduction in area between internal dies: .. 16 drafts 20.5% (26% elongation).

• Reduction in final die area (quick change): 1 draft 5.6 ~ 20.5% (6 – 26% elongation).

• Dies dimensions ø: 25 x 10 mm.

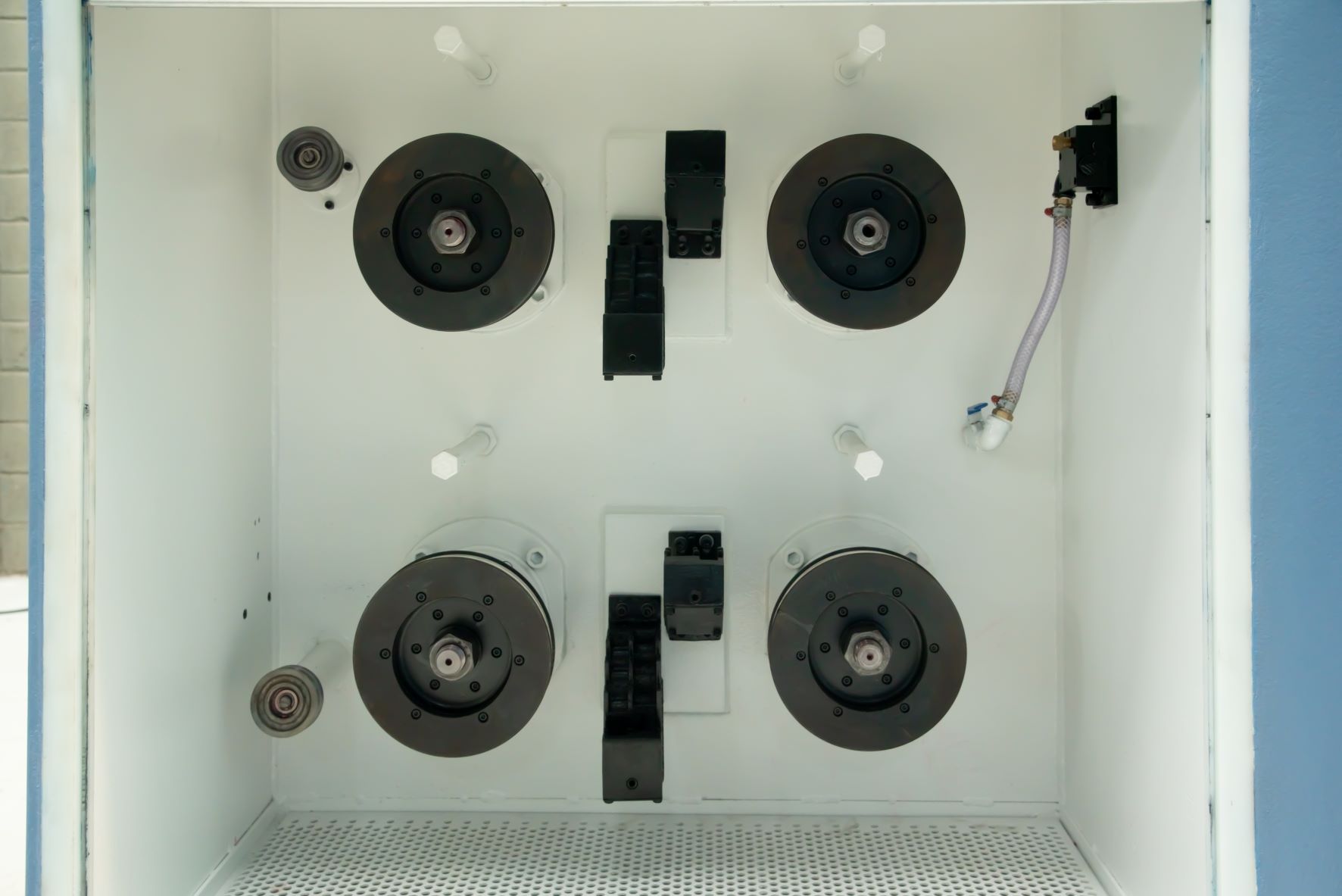

• No. of internal drawing cones and external capstan in tempered steel: 4 + 1.

• Silent transmission through flat conveyors.

• The wire drawing compartment and die holders are accessible through a sliding door, designed to prevent fluid leaks during operation.

• Integrated continuous 400 or 600A annealer.

• The wire drawing fluid distribution system is performed by pipes and dies holders especially designed to ensure proper dies lubrication.

• 350-liter tank for drawing solution + 280-liter tank for cooling solution with pumps and heat exchangers for cooling and circulation that can be interconnected with central system.

• Cantilevered shaft take-up, with embedded controller dancers, for DIN 400 steel coils with a capacity of approx. 100 kg of copper.

• Operating voltage: ………. 380 V. 60 Hz (Other to be confirmed).

Supplementary equipment:

• Payoff.

• Wire welding machine.

• Pre-thinning module for 2 wires with 2 drafts.

• Filter with paper blanket for lubricating solution.