Application / Product Range:

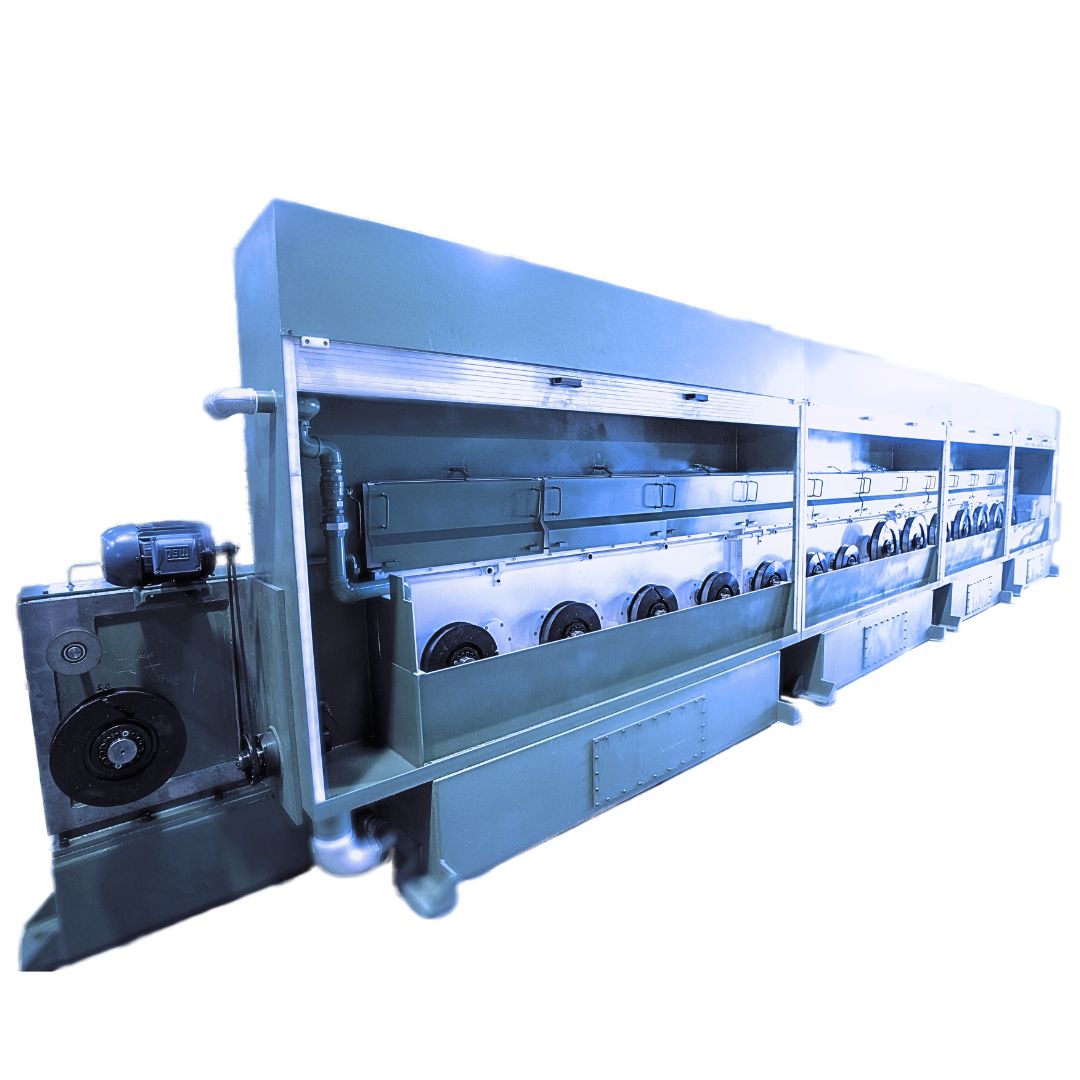

• For wet drawing of bare copper wire or aluminum and its alloys.

• Nº of wires: 01 or 02.

Technical data

(we reserve the right to modify technical data and characteristics at any time):

• Wet drawing for non-ferrous materials, tandem drawing system.

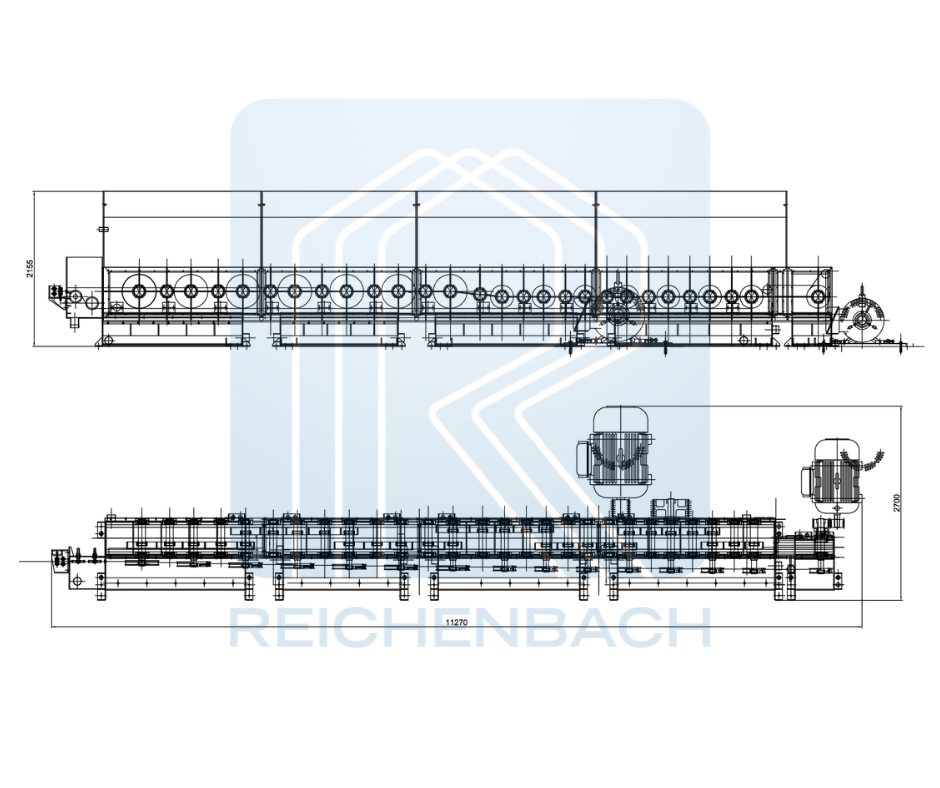

• Direction of operation: Right.

• Maximum operating speed: 30 m/s.

• Max. ø for copper inlet mm: 8.00.

• Max. ø for aluminum inlet mm: 9.50.

• Min./max. outlet ø mm: 1.30/4.20.

• Nº of drafts (*): 15.

• Die dimensions ø: 50 x 36 mm.

• Reduction in area between dies: 7 drafts 24.8 % (33 % elongation).

8 drafts 20.6 % (26 % elongation).

• Rotating end-die.

• Steel drawing rings, 7 x ø 450 + 8 x 300 mm, coated on Tungsten Carbide.

• Final diameter quick change system allows the change of the wire gauge by replacing only the last die and keeping the internal ones in their positions.

• Equipped with 2 drives, one for the internal capstans and one for the final external capstan.

• Gear transmission in oil bath.

• Die holders immersed in drawing bath capstans semi-immersed in drawing bath.

• The wire drawing compartment and die holders are accessible through sliding doors and tilting protectors, designed to prevent fluid leaks from the lubricant bath.

• Lower collector tank of drawing lubricant, configured for interconnection with centralized system.

• Operating voltage: 380V 60 Hz (Other to be confirmed).

• Jogging command (with pedals), for mounting dies on the machine.

(*) The drawing machine can be manufactured from 5 to 15 drawing drafts.

Supplementary equipment:

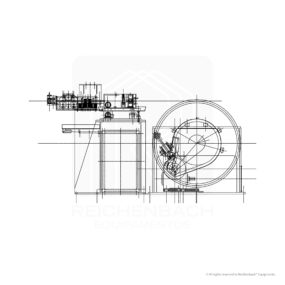

• Rod payoff.

• Rod welding machine.

• Rod sharpener.

• Continuous annealer, 3,500 to 6,000A. (For copper)

• Speed control and winding tension control dancer.

• Single or double automatic take up for DIN 630 or 800mm spools.

• Downcoiler Machine (Cages) Ø 600mm or ø 800mm or ø 1000mm.